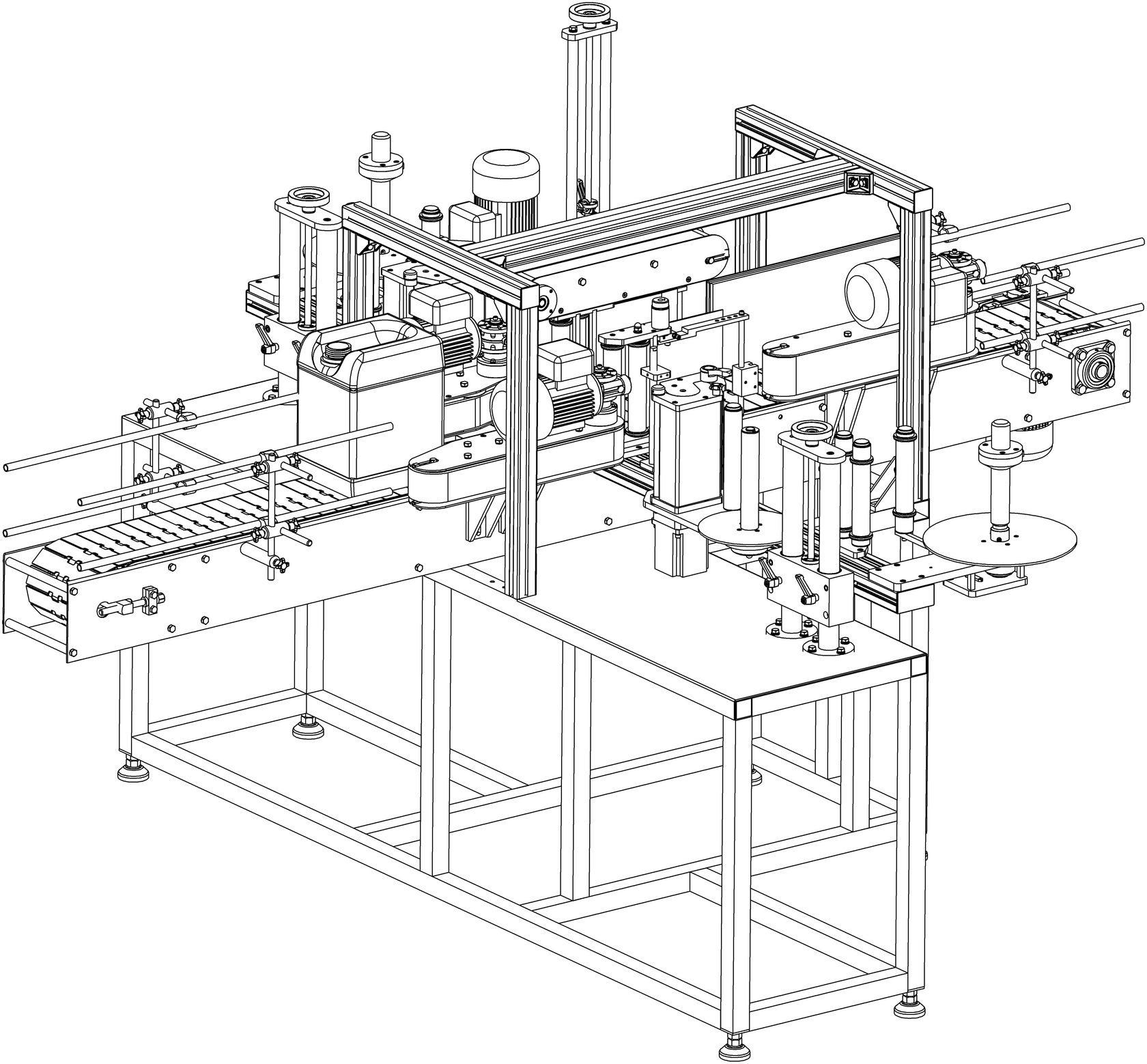

It is used for application of self-sticking label

to сylindrical, rectangular and oval containers.

to сylindrical, rectangular and oval containers.

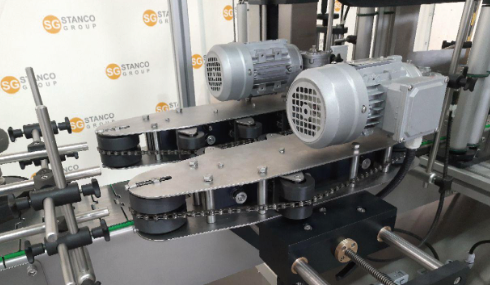

HOLDING CONVEYOR

It provides unsteady containers holding while labeling.

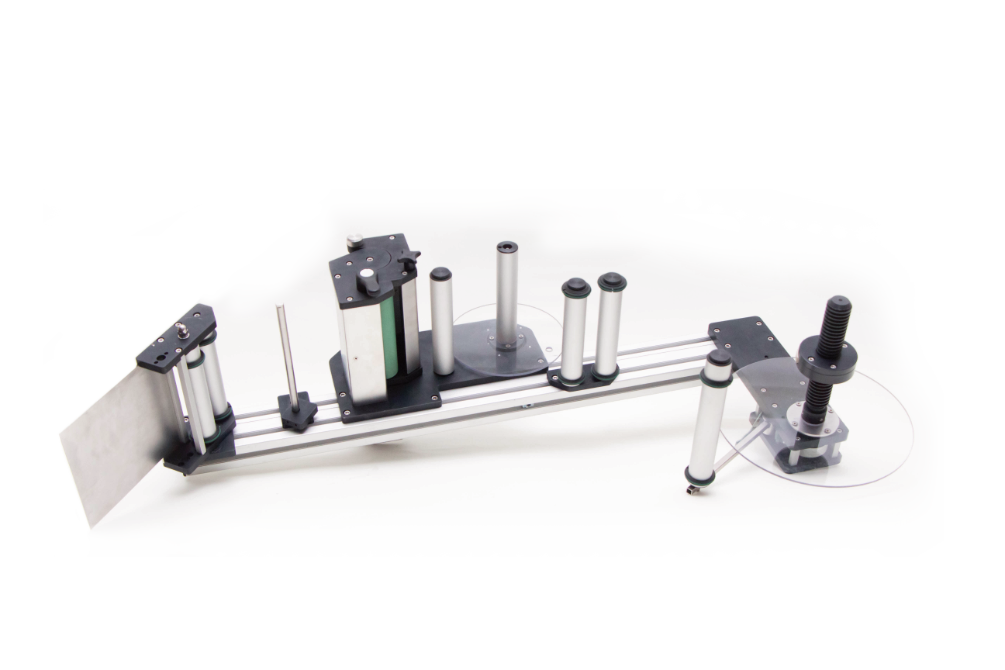

CONTAINER ALIGNMENT SYSTEM

It provides steady position of oval containers.

LABELER

removes label from body paper and applies it to the container. It may be manufactured in two dimension-types

depending on the label height (150 mm/250 mm).

depending on the label height (150 mm/250 mm).

WRAP-AROUND LABELER

It is used to apply the labels to сylindrical containers.

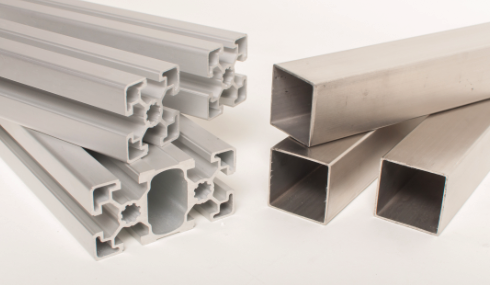

FRAME

It is manufactured of stainless steel with structural parts made of aluminum with anodic coating.

LABEL SENSOR

It provides operation of the labeler.

May be of two types:

— optical sensor (for opaque label)

— ultrasonic sensor (for no-label look application).

May be of two types:

— optical sensor (for opaque label)

— ultrasonic sensor (for no-label look application).

SPECIFICATIONS:

Type of label: self-sticking, in a roll

Capacity: up to 350* cpm

* Providing conveyor top speed and distance between bottles 200 mm

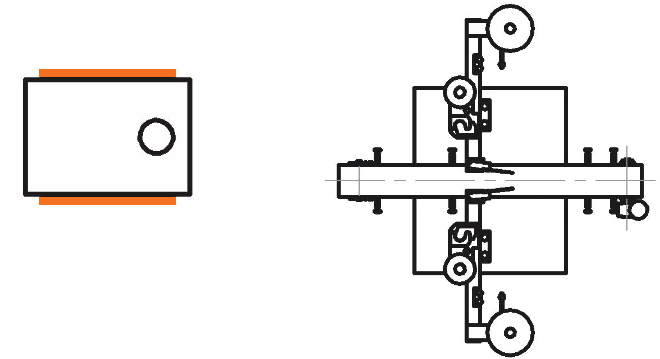

Number of labelers: 2

Actuator: electric

Power supply:

— voltage: 220 V

— frequency: 50 Hz

Power consumption: up to 1,9 kW

Overall dimensions: L2000xW2300xH1700 mm

Weight: 245 kg

Materials: AISI 304, alloy 2024.

Capacity: up to 350* cpm

* Providing conveyor top speed and distance between bottles 200 mm

Number of labelers: 2

Actuator: electric

Power supply:

— voltage: 220 V

— frequency: 50 Hz

Power consumption: up to 1,9 kW

Overall dimensions: L2000xW2300xH1700 mm

Weight: 245 kg

Materials: AISI 304, alloy 2024.

CONFIGURATIONS:

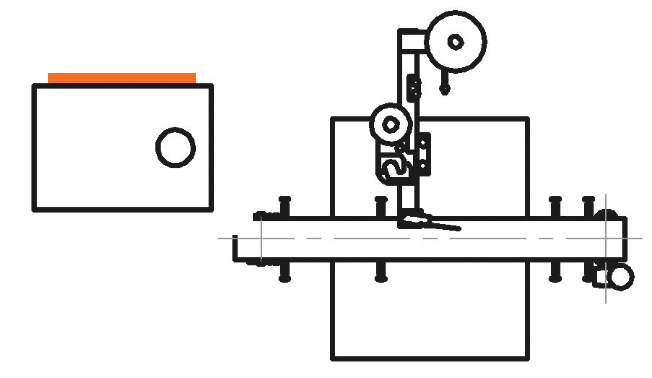

Rectangular/oval containers (1 label)

Rectangular/oval/сylindrical containers (1 label)

Rectangular/oval containers (front label and back label)

Rectangular/oval/cylindrical containers (front label and back label)

AUTOMATIC LABELING MACHINE